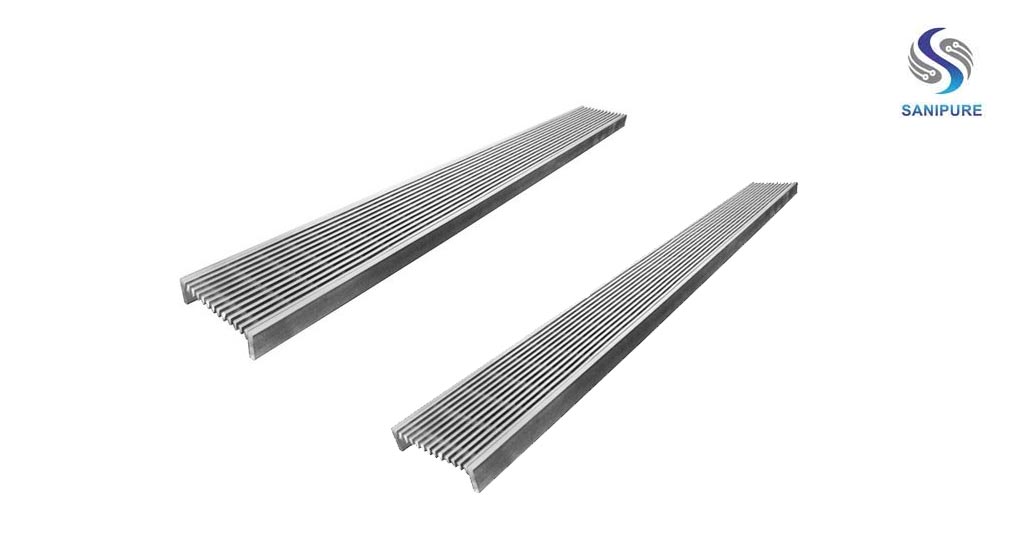

Stainless steel channel drains are indispensable components in pharmaceutical plants, designed to meet the industry’s stringent hygiene and safety standards. With their superior durability, chemical resistance, and easy maintenance, these drainage systems ensure a sterile and contamination-free environment, essential for manufacturing medicines and medical products.

Why Are Stainless Steel Channel Drains Essential in Pharmaceutical Plants?

Pharmaceutical plants adhere to strict sanitation protocols to prevent contamination during drug production. Stainless steel channel drains play a critical role in maintaining these standards by:

- Efficiently removing surface water and eliminating stagnant water.

- Preventing bacterial growth with their smooth, non-porous surfaces.

- Ensuring compliance with ISO 14644 standards for cleanrooms.

Key Benefits of Stainless Steel Channel Drains

- Hygienic Design

Stainless steel’s non-porous surface prevents the buildup of bacteria, mold, and other contaminants. This makes it an ideal choice for cleanrooms and production areas where sterility is paramount.

- Durability and Corrosion Resistance

- Resistant to extreme temperatures and harsh cleaning chemicals.

- Long-lasting performance, even in environments exposed to saline or acidic substances.

- Ease of Cleaning

Stainless steel channel drains are designed for quick and efficient cleaning, reducing downtime and ensuring uninterrupted operations.

- Chemical Resistance

Grade 316 stainless steel, enriched with molybdenum, offers enhanced resistance to chemicals and volatile organic compounds, making it ideal for pharmaceutical use.

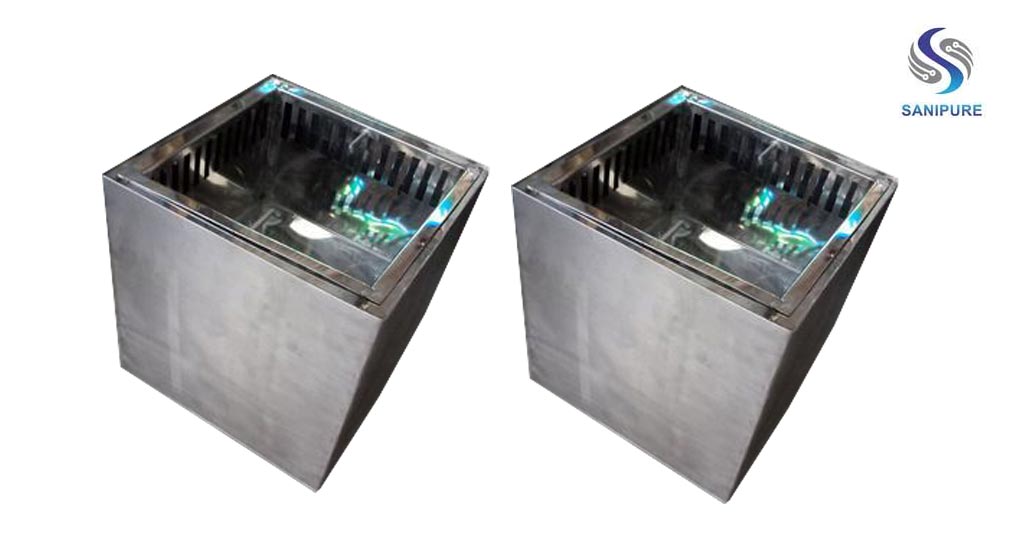

- Contamination Prevention

Sealed designs with features like O-ring gaskets and blind covers prevent wastewater and odors from contaminating cleanrooms.

Applications of Stainless Steel Channel Drains in Pharmaceutical Plants

- Cleanrooms

- Maintain sterility by efficiently draining water and preventing microbial growth.

- Sealed drainage systems ensure a controlled atmosphere free from contaminants.

- Production Areas

- Handle spills of chemicals and other liquids without corroding.

- Ensure smooth operations with durable and reliable drainage systems.

- Storage and Containment

- Prevent contamination of sensitive materials stored in pharmaceutical facilities.

- Durable construction supports heavy storage equipment.

- Laboratories

- Manage chemical spills and maintain a clean, safe working environment.

- Ensure compliance with hygiene standards for research and testing.

Choosing the Right Stainless Steel Channel Drain

- Material Grade

- Grade 316 Stainless Steel: Best suited for pharmaceutical environments due to its superior corrosion resistance and durability.

- Grade 304 Stainless Steel: Suitable for less corrosive environments but not recommended for exposure to high saline or acidic substances.

- Design Features

- Internal rounded corners for easy cleaning and enhanced hygiene.

- Clamping flanges for PVC flooring to create a watertight seal.

- Sealed covers with O-ring gaskets to prevent contamination.

- Compliance with Standards

Ensure the drainage system complies with ISO 14644 and other relevant pharmaceutical industry regulations.

Best Practices for Stainless Steel Channel Drains in Pharmaceutical Plants

- Regular Maintenance

- Schedule routine inspections to check for wear and tear.

- Clean drains thoroughly to prevent bacterial growth and contamination.

- Custom Fabrication

- Opt for custom-designed channel drains to meet specific facility requirements.

- Ensure proper sizing and placement for optimal performance.

- Integration with Flooring

- Use clamping flanges for a seamless fit with PVC flooring, ensuring no gaps for bacterial growth.

- Incorporate odor traps and filter baskets for improved hygiene.

Why Stainless Steel is the Material of Choice for Pharmaceutical Plants

- Hygienic Properties

Stainless steel’s smooth, non-porous surface resists microbial growth, ensuring clean and sterile environments.

- Chemical and Temperature Resistance

The addition of molybdenum in Grade 316 stainless steel enhances its ability to withstand harsh chemicals and extreme temperatures.

- Longevity and Sustainability

- Stainless steel is 100% recyclable, making it an eco-friendly choice.

- Its durability reduces the need for frequent replacements, saving costs in the long run.

Enhance Your Pharmaceutical Plant with Premium Stainless Steel Channel Drains

For reliable, hygienic, and durable drainage solutions, choose stainless steel channel drains tailored to the needs of pharmaceutical plants. Explore top-quality products designed for optimal performance and compliance with industry standards.

- Visit: Stainless Steel Drainage System

- Learn more: Pharmaceutical Drain Traps

- Contact us: Sanipure Systems Contact

FAQs about Stainless Steel Channel Drains

- Why is stainless steel preferred for pharmaceutical drains?

Stainless steel’s hygienic properties, durability, and resistance to corrosion make it ideal for pharmaceutical environments.

- What grade of stainless steel is best for pharmaceutical plants?

Grade 316 stainless steel is recommended due to its enhanced resistance to chemicals and extreme conditions.

- How do sealed channel drains benefit cleanrooms?

Sealed channel drains prevent wastewater and odors from contaminating the sterile environment, ensuring compliance with hygiene standards.