Why CIP Drain Traps Are Essential for Hygienic Processes

CIP (Clean-In-Place) drain traps are indispensable in maintaining high sanitation standards across various industries, such as food, beverage, dairy, and pharmaceuticals. These traps ensure the seamless removal of cleaning fluids and debris while preventing contamination, making them critical for facilities that prioritize hygiene compliance.

What Are CIP Drain Traps?

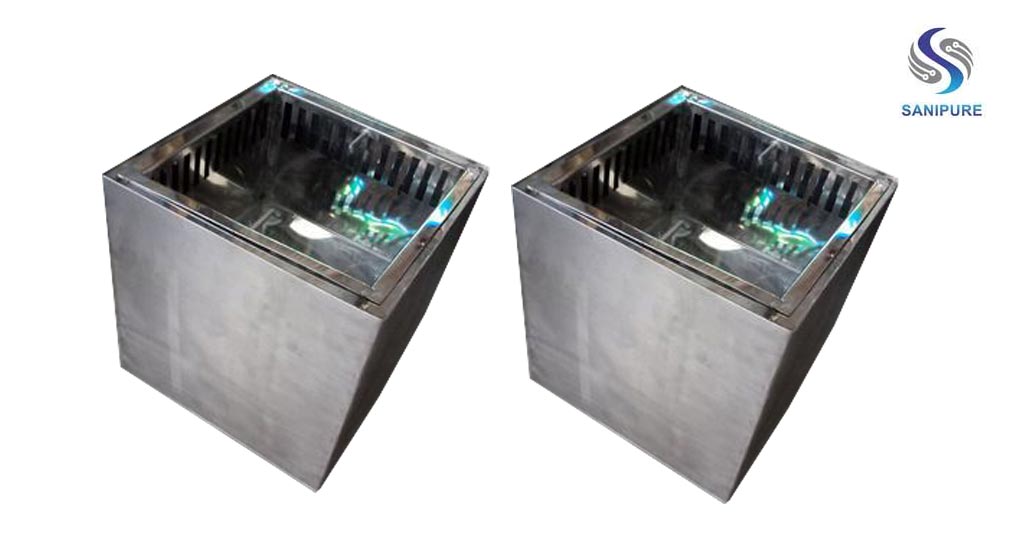

CIP drain traps are integral to Clean-In-Place systems, ensuring the sterile removal of cleaning fluids, debris, and contaminants during automated cleaning cycles. These traps prevent backflow, cross-contamination, and the ingress of harmful gases, maintaining a controlled and hygienic environment. Built from corrosion-resistant materials like stainless steel, they provide long-lasting durability and reliable performance in rigorous industrial applications.

Key Benefits of CIP Drain Traps

- Preventive Contamination Control

CIP drain traps are designed to capture waste particles and prevent them from entering the clean system. This proactive approach significantly reduces contamination risks, ensuring a sterile environment for production processes.

- Hygiene Maintenance

By isolating the drainage system from the clean production area, CIP drain traps maintain high sanitation standards, which are critical in industries like dairy processing and pharmaceutical manufacturing.

- Air Leak-Proof Design

Most CIP drain traps feature air-tight seals to block harmful gases or pathogens from entering the system. This design ensures sterility and prevents microbial risks during cleaning operations.

- Easy Cleaning and Inspection

Modern CIP drain traps are equipped with accessible designs, allowing for convenient cleaning and inspection. This feature ensures optimal functionality and compliance with hygiene regulations.

- Corrosion Resistance

Constructed from high-quality stainless steel, CIP drain traps resist harsh cleaning chemicals and ensure long-term durability, even in demanding environments.

- Optimized Drainage Efficiency

The advanced design of CIP drain traps facilitates efficient drainage of cleaning solutions without compromising the cleaning process. This ensures faster cycle times and reduced water usage.

- Reduced Maintenance Costs

By preventing clogs and minimizing frequent dismantling, CIP drain traps reduce maintenance efforts and associated costs, offering a cost-effective solution for industries.

How CIP Drain Traps Enhance Clean-In-Place Systems

- Automation for Error-Free Cleaning

CIP systems integrate with drain traps to automate cleaning processes, minimizing human errors and ensuring consistent results. This automation is particularly advantageous for large-scale operations where hygiene is non-negotiable.

- Utility Savings

By enabling efficient drainage and reusing water from specific cleaning stages, CIP systems reduce water and energy consumption. CIP drain traps play a pivotal role in ensuring the system operates smoothly and sustainably.

- Enhanced Product Quality

Reliable cleaning ensures contamination-free production lines, leading to consistent product quality and fewer recalls. This builds consumer trust and enhances brand reputation.

Applications of CIP Drain Traps Across Industries

- Food and Beverage Manufacturing

CIP drain traps maintain hygiene in food processing lines, preventing cross-contamination from drainage systems. This ensures compliance with food safety standards.

- Pharmaceutical Production

CIP drain traps isolate the drainage system from sterile environments, ensuring the production of contamination-free drugs and pharmaceuticals.

- Dairy Industry

In dairy plants, where cleanliness is critical, CIP drain traps support stringent sanitation standards by effectively handling residues like milk fats and proteins.

- Cosmetics and Chemicals

CIP drain traps also find applications in cosmetic and chemical industries, where high hygiene levels are essential to prevent contamination during production.

Optimizing CIP Processes with Drain Traps

Steps to Implementing CIP Systems

- Pre-Rinse: Removes surface residues using water or air.

- Caustic Wash: Cleans fats and proteins with hot water and sodium hydroxide.

- Intermediate Rinse: Rinses off detergent residue.

- Sanitizing Rinse: Eliminates microorganisms for a sterile environment.

- Final Rinse: Uses deionized water to prepare the system for the next cycle.

Best Practices

- Ensure piping and equipment are designed for CIP compatibility.

- Use stainless steel CIP drain traps for durability and corrosion resistance.

- Regularly clean and inspect drain traps to maintain efficiency.

Frequently Asked Questions (FAQs)

Q1. What is a CIP drain trap?

A CIP drain trap is a specialized component in Clean-In-Place systems designed to manage drainage while preventing contamination and maintaining hygiene.

Q2. Why are CIP drain traps important in dairy plants?

CIP drain traps prevent cross-contamination and ensure thorough cleaning of processing equipment, crucial for maintaining dairy product safety and quality.

Q3. How do CIP drain traps reduce maintenance costs?

By preventing clogs and minimizing the need for frequent dismantling, CIP drain traps reduce the frequency of maintenance activities, saving time and money.

Ensure optimal hygiene and efficiency in your processing facility with premium CIP drain traps. Visit our CIP Drain Trap page or Stainless Steel Drainage System for more information and inquiries.