Introduction: The Critical Role of Drainage Systems in Pharmaceuticals

In the pharmaceutical industry, where maintaining sterile conditions is non-negotiable, drainage systems play a pivotal role in ensuring cleanliness and hygiene. Sterile floor drain traps are essential components designed to prevent contamination, control microbial growth, and facilitate smooth wastewater management in cleanrooms and other critical areas. With high standards for sanitation and performance, these specialized traps are engineered to meet stringent industry requirements.

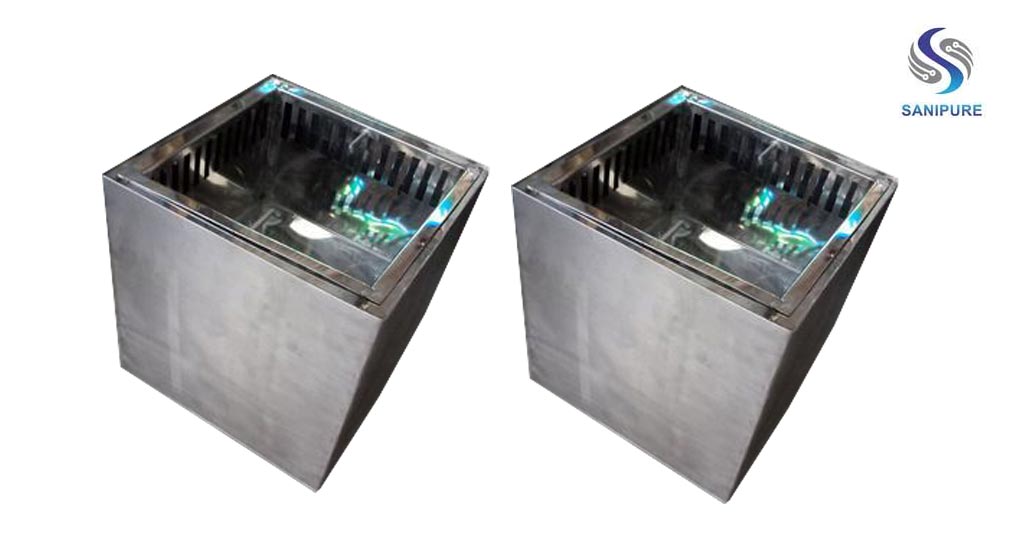

What Are Sterile Floor Drain Traps?

Sterile floor drain traps are advanced drainage solutions made of high-grade stainless steel, typically SS 316, to provide exceptional durability, corrosion resistance, and compliance with pharmaceutical hygiene standards. These traps are specifically designed to:

- Prevent the passage of solids and debris into the drainage system.

- Eliminate odors and microbial growth.

- Maintain a sealed, sterile environment in cleanrooms and processing areas.

Key Features of Sterile Floor Drain Traps

- Material Excellence: Why Stainless Steel 316?

Grade 316 stainless steel is the preferred choice for pharmaceutical drainage systems because:

- Superior Corrosion Resistance: Contains molybdenum for enhanced resistance to chlorides and acids.

- Hygienic Surface: Non-porous and easy to clean, preventing bacterial growth.

- Durability: Withstands aggressive cleaning agents and high-pressure cleaning.

- Innovative Design for Maximum Efficiency

- Side Outlets: Facilitate efficient drainage while maintaining a compact footprint.

- Removable Covers: Simplify cleaning and maintenance without disrupting operations.

- Hygienic Features: Includes rounded corners, odor traps, and filter baskets for thorough cleaning and optimal hygiene.

- Blind Covers with O-Ring Gaskets: Seal the drainage system to prevent bacteria and contaminants from re-entering cleanrooms.

- Customizable Shapes and Sizes

- Square and Circular Profiles: Tailored to fit diverse floor layouts.

- Standard Dimensions: Common sizes like 300×300 mm with a 4-inch outlet for universal applications.

Why Are Sterile Drain Traps Essential in Pharmaceuticals?

- Meeting Stringent Hygiene Standards

Pharmaceutical production involves cleanrooms regulated by ISO 14644 standards, where even microscopic contamination can compromise drug safety. Sterile floor drain traps are designed to meet these exacting standards, ensuring a sterile environment.

- Prevention of Microbial Growth

These traps prevent stagnant water, odors, and backflow, which could otherwise harbor bacteria or other pathogens in cleanrooms.

- Seamless Integration in Cleanrooms

From laboratories to production areas, sterile traps integrate seamlessly with specialized flooring like PVC, using clamping flanges to ensure airtight and watertight seals.

Applications of Sterile Floor Drain Traps in the Pharmaceutical Industry

- Cleanrooms: Maintain aseptic conditions by ensuring efficient drainage and preventing backflow.

- Processing Areas: Manage wastewater from cleaning, sterilization, and production processes.

- Storage Rooms: Protect sensitive materials by eliminating water stagnation and contamination risks.

- Laboratories: Ensure compliance with hygiene regulations in quality control and research labs.

Installation and Maintenance Guidelines for Sterile Drain Traps

Installation

- Correct Positioning: Ensure proper slopes (1:80 or higher) in floors for optimal wastewater flow.

- Industry Compliance: Adhere to ISO and GMP standards during installation.

Maintenance

- Regular Cleaning: Remove covers and clean traps with approved detergents.

- Periodic Inspections: Check for wear, corrosion, and seal integrity.

- Replace Components: Timely replacement of worn-out gaskets and filter baskets ensures consistent performance.

Advantages of Using Sterile Floor Drain Traps in Pharma Facilities

- Unmatched Hygiene: Keeps bacteria and contaminants out of cleanrooms.

- Enhanced Durability: Stainless steel construction ensures long-lasting performance.

- Odor Control: Eliminates foul smells to maintain a sterile environment.

- Easy Maintenance: Removable components simplify cleaning, saving time and labor.

- Regulatory Compliance: Meets GMP, ISO 14644, and other pharmaceutical standards.

FAQs About Sterile Floor Drain Traps

Q1. Why is stainless steel 316 recommended for pharmaceutical drainage systems?

Grade 316 contains molybdenum, providing superior corrosion resistance and ensuring hygiene in saline or acidic environments.

Q2. How do sterile drain traps prevent contamination?

These traps use O-ring gaskets and blind covers to seal the system, preventing bacteria and contaminants from entering cleanrooms.

Q3. Can sterile drain traps be customized?

Yes, traps are available in various sizes, shapes, and configurations to meet specific pharmaceutical requirements.

Q4. What maintenance is required for sterile floor drain traps?

Regular cleaning, inspection, and component replacement (such as gaskets and filters) are essential for maintaining performance and hygiene.

Ensure flawless hygiene in your pharmaceutical facility with premium sterile floor drain traps. Visit Sanipure Systems for innovative drainage solutions or Contact Us to discuss your specific requirements.