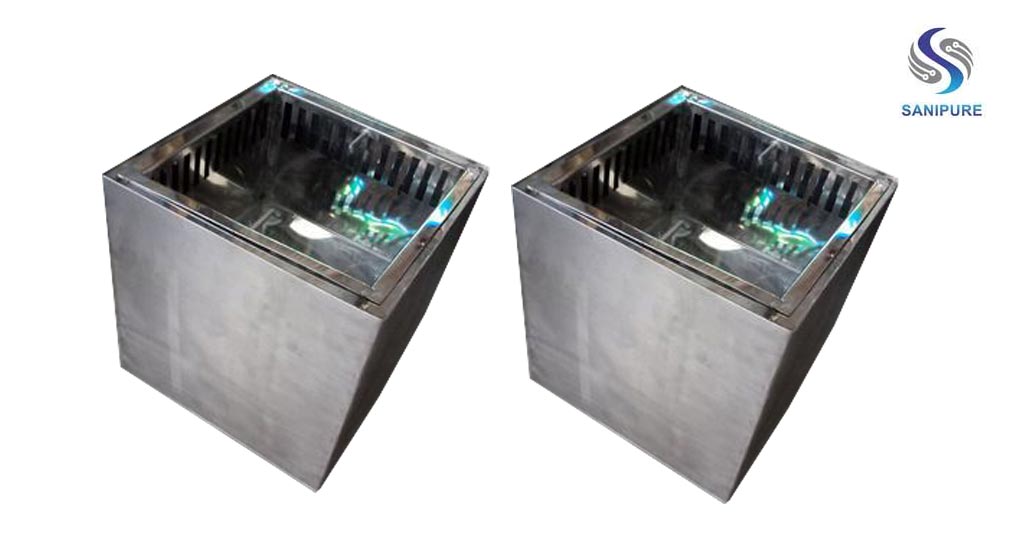

What Are Stainless Steel Floor Drain Strainers?

Stainless steel floor drain strainers are essential components of drainage systems, designed to prevent solid debris from clogging plumbing systems. Typically made from corrosion-resistant stainless steel, these strainers feature a perforated or slotted design that allows water to flow through while capturing larger particles such as hair, food waste, or industrial debris. Their durable design ensures they perform efficiently in various environments, from residential bathrooms to industrial facilities.

Key Features of Stainless Steel Floor Drain Strainers

- Material Benefits of Stainless Steel

Stainless steel is the preferred material for floor drain strainers due to its exceptional properties:

- Corrosion Resistance: With its high chromium content, stainless steel resists rust and corrosion even in damp or chemically exposed environments.

- Durability: The robust nature of stainless steel ensures a long lifespan, reducing the need for frequent replacements.

- Hygienic Properties: Stainless steel is easy to clean and resists bacterial growth, making it ideal for applications where sanitation is critical.

- Design Features

Stainless steel floor drain strainers are engineered with the following design elements:

- Perforations and Slots: Strategically placed holes or slots allow for optimal water flow while capturing debris of varying sizes.

- Grate Patterns: Available in different patterns to suit specific needs, such as finer perforations for bathrooms and larger slots for industrial use.

- Removable Design: Many strainers feature a lift-out design, enabling easy cleaning and maintenance.

- Enhanced Durability Through Quality Construction

- High-Grade Stainless Steel: Premium grades like 304 or 316 stainless steel are commonly used, with 316 offering superior resistance to chemicals and saltwater.

- Robust Construction: Precision welding and high-quality manufacturing ensure the strainer withstands daily wear and tear.

- Leak Prevention: Gasket designs in some models create a tight seal around the drain, preventing leaks and enhancing performance.

Applications of Stainless Steel Floor Drain Strainers

- Residential Bathrooms

Stainless steel strainers are commonly used in showers and bathtubs to prevent hair, soap residue, and other debris from clogging the drainage system.

- Commercial Kitchens

In food preparation areas, these strainers catch food scraps, grease, and other waste, ensuring smooth drainage and compliance with hygiene standards.

- Industrial Facilities

Factories, food processing plants, and other industrial spaces benefit from heavy-duty strainers that can handle large debris and chemical exposure.

- Public Spaces

Public restrooms, swimming pools, and gyms rely on stainless steel strainers for efficient water drainage and debris control.

Maintenance and Cleaning Tips for Long-Term Performance

- Regular Debris Removal

Lift the strainer periodically to remove trapped debris, preventing blockages and maintaining water flow.

- Cleaning Method

Wash the strainer using warm water and a mild detergent. For stubborn residue, use a soft-bristled brush.

- Inspection for Damage

Check for signs of wear, corrosion, or damage. Replace the strainer if its performance is compromised.

- Avoid Harsh Chemicals

While stainless steel is resistant to many chemicals, avoid using abrasive cleaners or tools that can scratch the surface.

Why Choose Stainless Steel Floor Drain Strainers?

- Unmatched Durability

Stainless steel’s corrosion-resistant properties ensure a long lifespan, making it a cost-effective solution for drainage systems.

- Versatile Applications

From homes to industrial facilities, stainless steel floor drain strainers are adaptable to various environments and requirements.

- Eco-Friendly and Recyclable

Stainless steel is a sustainable material, offering an environmentally friendly option for long-term use.

Frequently Asked Questions (FAQs)

Q1. Why is stainless steel preferred for floor drain strainers?

Stainless steel is highly durable, corrosion-resistant, and hygienic, making it ideal for use in wet and chemically exposed environments.

Q2. How do I clean a stainless steel floor drain strainer?

Simply remove the strainer, wash it with warm water and mild detergent, and scrub gently with a brush to remove debris.

Q3. Can stainless steel strainers be customized for specific applications?

Yes, stainless steel strainers are available in various sizes, patterns, and grades to meet different drainage needs.

Q4. What grade of stainless steel is best for floor drain strainers?

Grade 316 stainless steel is preferred for environments exposed to chemicals or saltwater, while grade 304 is suitable for most standard applications.

Upgrade your drainage system with premium stainless steel floor drain strainers. Visit our Stainless Steel Floor Drain Strainers page or explore more Stainless Steel Drainage Systems. Contact us for expert solutions tailored to your needs.