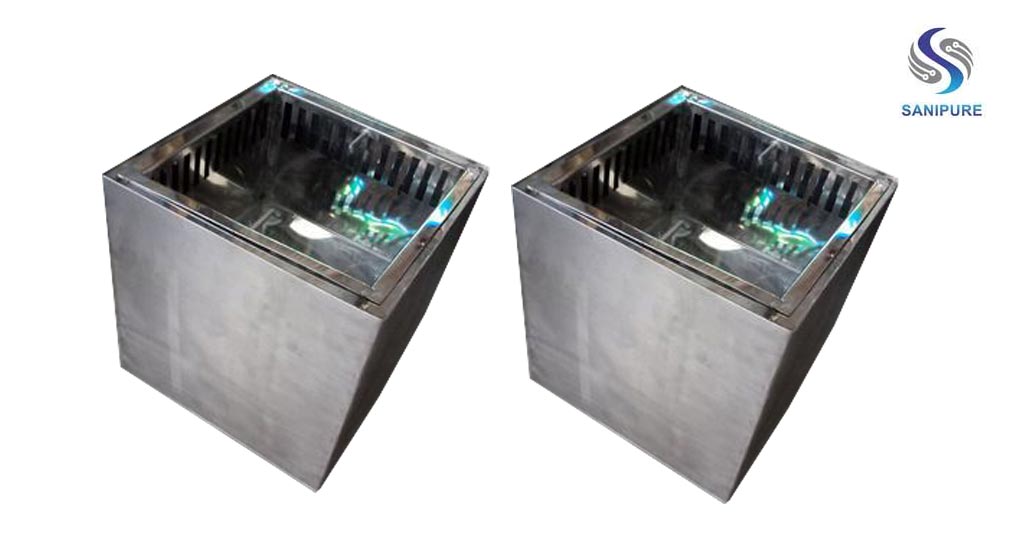

What Are Stainless Steel Drain Boxes?

Stainless steel drain boxes are enclosed floor drainage units designed to collect and channel wastewater from industrial, commercial, or sanitary areas. Typically made from SS304 or SS316L, they feature grating tops, internal sumps, and outlet piping—ensuring efficient drainage, hygiene, and corrosion resistance across demanding environments.

Why Proper Maintenance is Critical for Long-Term Use

Drain boxes are essential for keeping facilities dry, safe, and sanitary. Without regular upkeep, even stainless steel systems can suffer from:

- ➖ Debris buildup and clogging

- ➖ Biofilm or bacterial growth in food and pharma units

- ➖ Surface discoloration or pitting corrosion

- ➖ Reduced flow performance and foul odor issues

With proper care, SS drain boxes can last 15–20 years without significant degradation, supporting your drainage compliance, safety, and hygiene goals.

Trends, Challenges & Common Maintenance Queries

🔼 Industry Trends:

- Shift toward modular SS drainage systems with easy-clean designs

- Use of SS316L drain boxes in corrosive washdown areas

- Emphasis on CIP (Clean-in-Place) drainage compatibility in food/pharma plants

❓ Common Questions:

- How often should drain boxes be cleaned?

- Can surface rust form on stainless steel?

- What chemicals are safe for SS drain maintenance?

- Is 304 or 316 better for aggressive environments?

🔗 Explore Stainless Steel Drain Boxes

Best Practices for Cleaning and Maintaining SS Drain Boxes

At Sanipure, we recommend a structured inspection, cleaning, and sanitation routine to keep your stainless steel drain boxes working at peak efficiency.

Here’s how to maximize their service life:

✅ 1. Daily Surface Inspection

- Check for visible debris, food residue, or sludge buildup on the grating.

- Ensure grating or perforated tops are not bent, blocked, or dislodged.

- In wet processing areas, ensure water is flowing freely through the outlet.

✅ 2. Weekly Internal Cleaning

- Remove the grating and flush the box with hot water or pressurized cleaning jets.

- Scrub the internal box surface with non-abrasive brushes and neutral pH detergents.

- Avoid harsh acids or chlorides that may cause pitting in SS304; prefer SS316L for aggressive areas.

✅ 3. Monthly Deep Maintenance

- Inspect joints and outlet connections for leaks or gasket wear.

- Use stainless steel–safe descaling agents to remove mineral deposits.

- Reseal welds or joints with food-grade silicone if any gaps form.

✅ 4. Seasonal or Quarterly Actions

- Conduct flow rate testing to ensure drainage performance hasn’t reduced.

- Check anchoring and leveling of the box within the floor recess.

- In pharma or food zones, verify CIP sprayball systems or auto-cleaning devices are functioning properly.

Maintenance Table for Quick Reference

| Frequency | Task | Tools / Materials | Notes |

|---|---|---|---|

| Daily | Visual check, wipe down | Cloth, water | Remove debris early |

| Weekly | Grating removal, flush | Water jet, brush | Use pH-neutral detergent |

| Monthly | Internal inspection | Torch, descaler | Avoid chloride cleaners |

| Quarterly | Full system test | Flow gauge, level | Check seals and anchors |

Why Stainless Steel Still Needs Maintenance

Even though SS 304/316L is corrosion-resistant, regular exposure to:

- Wastewater with chemical or acidic byproducts

- Food residues or dairy enzymes

- High humidity or biofilm-prone conditions

…can result in surface etching, fouling, and reduced drainage efficiency.

Proper care ensures these issues never progress to costly downtime or regulatory failures.

Why Choose Sanipure Drain Boxes?

- ✅ Fabricated from SS 304 or SS 316L with smooth interiors and no crevice traps

- ✅ Compatible with CIP systems, U-traps, and floor slope designs

- ✅ Designed for easy grating removal and inline cleaning access

- ✅ Custom sizes and outlet configurations available

- ✅ Used in pharmaceutical, food, beverage, and industrial plants across India

We build drainage systems that perform for years—when paired with proper maintenance.

🔗 Explore Full Drainage System Solutions

Support for Maintenance Planning & System Upgrades

At Sanipure, we not only manufacture SS drain boxes but also assist in:

- 🛠️ Maintenance consultations for pharma, food & beverage clients

- 📐 Drain system design optimization for slope, flow rate, and cleaning access

- ⚙️ Spare part supply for gratings, seals, and inlets

- 🔧 Refurbishment or upgrade services for aging SS drainage systems

Whether you need a replacement box, cleaning SOP, or an entire system re-design, we’re here to help.

Buyer Tips: Getting the Most from Your SS Drain Box

✔️ Schedule monthly inspections even if surface appears clean

✔️ Avoid chloride-based cleaners, especially on SS304

✔️ Upgrade to SS316L if exposed to acidic fluids or chemicals

✔️ Always keep the grating flush with floor level to prevent tripping

✔️ Clean under grating to prevent biofilm and odor formation

→ Talk to Our Drainage Specialist Today

Voice Search Optimized FAQs

Q1. How often should stainless steel drain boxes be cleaned?

Basic cleaning should be done weekly, with deep cleaning monthly or quarterly depending on use.

Q2. Can stainless steel drain boxes rust?

While SS is corrosion-resistant, surface rust can occur if not cleaned properly or exposed to chlorides.

Q3. What’s the difference between SS304 and SS316L in drain boxes?

SS316L offers better corrosion resistance, especially in chemical, coastal, or acidic environments.

Q4. How do I remove stains or discoloration from SS drain boxes?

Use non-abrasive stainless-safe cleaners or descalers with neutral pH.

Q5. Can drain boxes be pressure cleaned?

Yes. Jet cleaning is effective—ensure grating is removed and connections are secure.

Q6. Are drain boxes reusable or one-time installations?

They are long-life, reusable components with replaceable gratings or seals if needed.

Q7. Is maintenance mandatory even if there’s no clogging?

Yes. Maintenance prevents buildup, bacteria, and long-term flow degradation.

Q8. Where can I get custom-size SS drain boxes or replacement parts?

From Sanipure Systems — with full technical support and design assistance.

Maintain Smart. Drain Better.

Your facility’s hygiene, safety, and compliance start with drainage.

A well-maintained SS drain box ensures clean flow, zero backup, and long-term efficiency.

🧰 Request a Custom Maintenance SOP

📥 Ask for Drain Box Size Chart or Brochure

📞 Schedule a Drainage Review with Sanipure

→ Contact Us Now

Stainless Steel that Lasts

Even the strongest materials need care.

With simple, regular maintenance, your Sanipure SS drain box will perform for years—quietly supporting your hygiene systems where it matters most.