What Is a Pharmaceutical Drainage System?

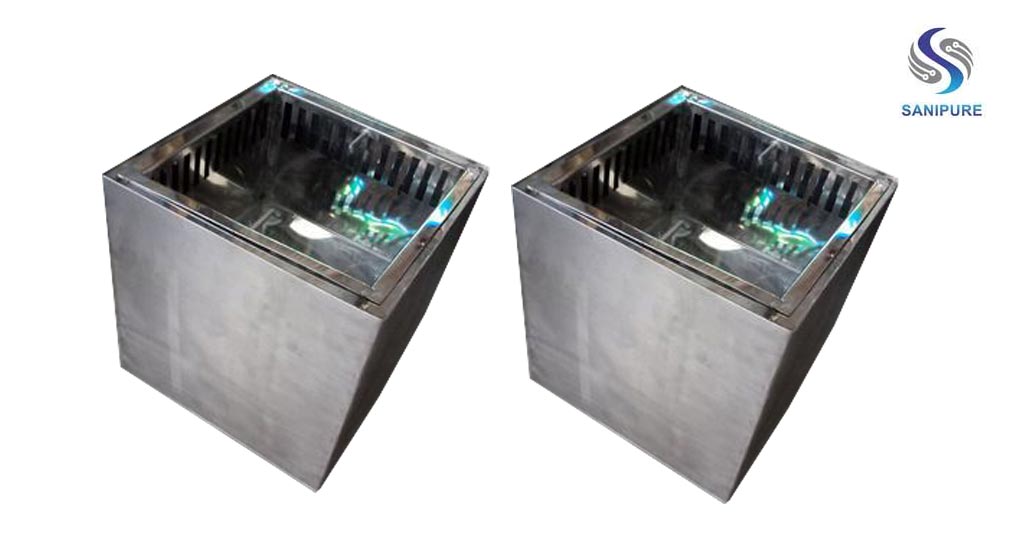

A pharmaceutical drainage system is a high-performance, hygienic wastewater network designed to handle chemical, biological, and process effluents in drug manufacturing and cleanroom environments. Built using stainless steel components (typically SS316L) such as drain traps, channels, gullies, and floor strainers, it ensures safe liquid discharge without microbial growth or cross-contamination.

Why Maintenance Matters in Pharma Environments

In pharmaceutical units, poor drainage maintenance can lead to:

- 🚨 Bacterial contamination and biofilm formation in drain outlets

- 🚫 Non-compliance with GMP, FDA, and WHO norms

- 💧 Backflow or standing water, disrupting cleanroom classifications

- 🧪 Chemical corrosion of unmaintained outlets, leading to structural leaks

Routine maintenance of the drainage system is not just about cleanliness—it’s critical to maintaining product quality, operator safety, and regulatory approval.

Industry Challenges & Common Questions

🔼 Pharma Drainage Trends:

- Integration of CIP (Clean-In-Place) compatible drainage components

- Demand for tamper-proof, bacteria-resistant designs

- Increased auditing of drainage inspection and cleaning logs

❓ FAQs Buyers Ask:

- How often should drains be cleaned in sterile areas?

- Can water stagnation affect product integrity?

- What is the role of SS316L in pharma drainage maintenance?

- How do I ensure my traps and strainers meet compliance standards?

🔗 Explore Stainless Steel Drainage Systems

🔗 View Pharmaceutical Drain Traps

How to Maintain Drainage Systems in Pharma Environments

At Sanipure Systems, we recommend a preventive maintenance strategy focused on hygiene, structural integrity, and compliance documentation. Here’s how to do it right:

🔧 1. Daily & Weekly Maintenance

- Clean drain covers, strainers, and gullies with approved neutral-pH, non-corrosive cleaners

- Ensure no standing water around the floor outlet

- Inspect for visible discoloration, deposits, or stagnant residues

🧪 2. Monthly Microbial Checks

- Conduct swab tests near floor drains, corners, and internal traps

- Sanitize using FDA-approved disinfectants to prevent biofilm formation

- Ensure no odor or microbial regrowth near sensitive areas

🧰 3. Quarterly Drain Trap Inspection

- Remove and inspect pharma-grade drain traps for scale, corrosion, or leakage

- Clean sediment baskets and inspect the integrity of water seals or gas traps

- Check that CIP spray heads or cleaning ports are functioning

🛠️ 4. Annual Performance Review

- Conduct flow testing to ensure there is no drain choke or buildup

- Review and update drainage logs, compliance certificates, and SOP documentation

- Replace worn-out gaskets, seals, or gratings to maintain hygiene standards

Pharma Drain Maintenance Table

| Maintenance Task | Frequency | Purpose |

|---|---|---|

| Drain grating cleaning | Daily / Weekly | Prevent clogs and surface fouling |

| Microbial sanitation | Monthly | Biofilm and contamination control |

| Trap inspection & cleaning | Quarterly | Seal integrity and debris removal |

| Drain flow performance test | Annually | Ensure drainage speed and no blockages |

| Documentation review | Annually | Regulatory audit readiness |

Features of Sanipure’s Pharma-Grade Drainage Components

- ✅ SS316L construction with electropolished interiors

- ✅ Zero crevice and slope-compliant design for full drainage

- ✅ Tamper-proof baskets and self-cleaning traps

- ✅ Fully autoclavable and CIP-compatible drain components

- ✅ Conforms to cGMP, FDA, and ISO cleanroom guidelines

We supply validated pharma drainage systems used in cleanrooms, sterile processing zones, biotech fermentation suites, and injectable units.

🔗 View Pharmaceutical Drain Traps

Why Sanipure?

- ✅ Trusted by India’s top formulation and bulk drug manufacturers

- ✅ Support for custom trap designs, validation, and project BOQs

- ✅ End-to-end delivery with installation, documentation, and after-sales support

- ✅ 100% stainless steel drainage ecosystem — traps, strainers, boxes, and channels

When pharma hygiene is non-negotiable, your drainage system must be clean, sealed, and always audit-ready.

Compliance-Support Drainage Solutions with Ongoing Maintenance Benefits

At Sanipure Systems, we go beyond supply—we support:

- 🛠️ Custom-fabricated pharma-grade traps and strainers

- 📄 Validation-ready documentation: drain logs, test reports, SOPs

- 🧪 Audit-focused design support for FDA, WHO-GMP, EU-GMP, and ISO compliance

- 🧰 On-request maintenance checklists tailored to your cleanroom class

- 🌍 Nationwide delivery and export support for pharma project sites

Our SS drainage systems are already installed in injectable units, biosimilar plants, hormone blocks, oncology labs, and OSD facilities.

Buyer Tips: Keeping Your Drains Pharma-Compliant

✔️ Use SS316L electropolished drain traps for cleanroom zones

✔️ Avoid plastic or PVC fittings—even in low-grade utilities

✔️ Maintain a cleaning and validation log tied to SOP documentation

✔️ Confirm CIP and autoclavability if operating in sterile or injectable areas

✔️ Partner with suppliers who understand GMP audit requirements

→ Request a Maintenance Checklist or Compliance-Ready Design

Voice Search Optimized FAQs

Q1. Why is drainage maintenance important in pharma plants?

It prevents contamination, ensures product safety, and maintains compliance with regulatory standards.

Q2. How often should pharmaceutical drains be cleaned?

Daily surface cleaning, monthly microbial checks, and quarterly trap inspections are recommended.

Q3. What grade of stainless steel is best for pharmaceutical drainage?

SS316L is ideal due to its superior corrosion resistance and suitability for cleanroom environments.

Q4. Are pharma-grade drain traps autoclavable?

Yes. Sanipure’s SS316L traps are designed to be fully autoclavable and CIP-compatible.

Q5. Can unmaintained drains cause product contamination?

Absolutely. Biofilm, backflow, and leaks from dirty drains can compromise sterile areas and batches.

Q6. Do regulators check drainage systems during audits?

Yes. GMP and FDA audits often review drain cleaning logs, trap designs, and zone-wise compliance.

Q7. What is the ideal drainage slope in cleanrooms?

A 1–2% slope is standard for effective self-draining and prevention of stagnation.

Q8. Where can I buy pharma-compliant drain traps in India?

From Sanipure Systems — your trusted partner for stainless steel cleanroom drainage.

Clean Drainage, Clean Compliance

Drainage is not just a utility—it’s a core pillar of GMP sanitation and operational integrity.

With Sanipure, you ensure drains that stay clean, validated, and always audit-ready.

🧾 Request a Validation SOP or Drain Maintenance Log Template

📥 Download Full Drain Trap Product Brochure

📞 Talk to Our Pharma Engineering Expert

→ Contact Sanipure Systems Now

Where Hygiene Starts Beneath the Surface

A single contaminated drain can cost a batch, a product license—or a company’s credibility.

Maintain every trap, every strainer, every channel—because in pharma, everything counts.