What Are Stainless Steel Powder Samplers?

Stainless steel powder samplers are precision instruments used in pharmaceutical and cleanroom environments to extract representative samples of dry powders, granules, or bulk solids from containers, drums, or blending vessels. Made from SS316L or SS304, these tools ensure GMP-compliant sampling without compromising the integrity or sterility of the batch.

Two primary types of powder samplers are commonly used:

- ✅ Single-Cavity Sampler: Collects one sample per insertion point

- ✅ Multi-Cavity Sampler: Collects multiple depth-layer samples in one insertion

Why Comparing Sampler Types Matters in Pharma

Selecting the wrong type of powder sampler can result in:

- ❌ Non-representative batch sampling

- 🚫 Cross-contamination risks

- ⚠️ GMP non-compliance in QC or QA audits

- 💸 Wasted product due to over-sampling or spillage

Choosing between single and multi-cavity designs depends on sampling objective, product uniformity, container depth, and zone classification.

Trends, Buyer Challenges & Voice-Search Questions

🔼 Pharma Trends in Powder Sampling:

- Transition from plastic to full stainless steel sampling tools

- Demand for fully autoclavable and laser-marked samplers

- Regulatory emphasis on layered sampling (multi-cavity) for batch uniformity checks

❓ Common Buyer Queries:

- What’s the difference between single and multi-cavity powder samplers?

- Which is better for granules or fine powder?

- Can these be used in sterile areas?

- Is SS316L necessary for powder samplers in cleanrooms?

🔗 Explore Stainless Steel Powder Samplers

Key Differences Between Single and Multi-Cavity Powder Samplers

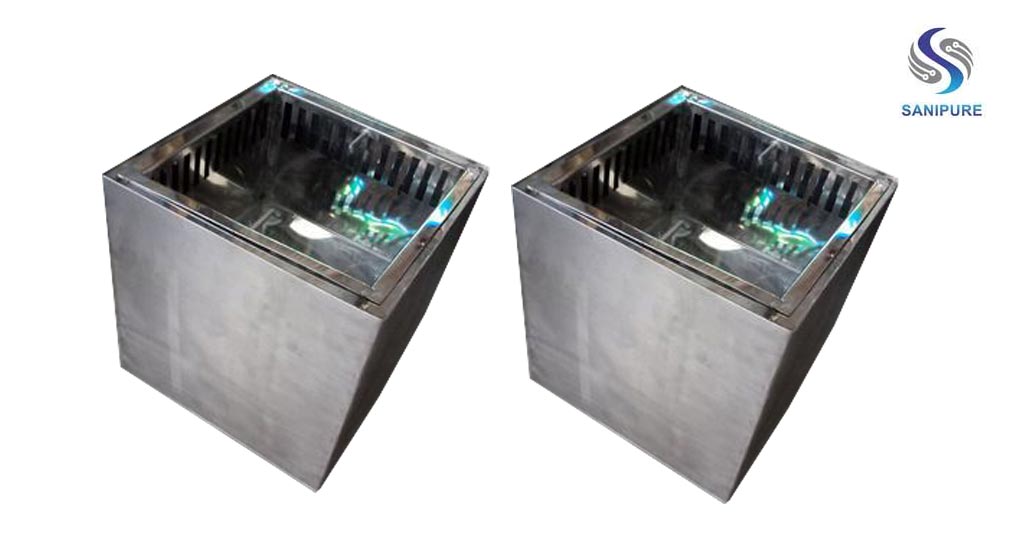

At Sanipure Systems, we design and manufacture both single-cavity and multi-cavity powder samplers from pharma-grade SS316L, suitable for cleanroom operations, GMP protocols, and sterile sampling.

Let’s break down their use cases and benefits.

Comparison Table: Single vs Multi-Cavity Samplers

| Feature | Single-Cavity Sampler | Multi-Cavity Sampler |

|---|---|---|

| Sampling Depth | One defined depth per insertion | Multiple layers in one insertion |

| Purpose | Point sampling | Cross-sectional / stratified batch sampling |

| Sample Volume Control | Manual | Uniform per cavity |

| Ideal For | Homogenous powders, small batches | Large drums, layered powders, granules |

| Design Simplicity | Simple, lightweight | More complex, heavier |

| Audit Compliance | Basic | High – supports risk-based stratified QA |

| Time Efficiency | Slower for multi-layer sampling | Faster, multiple layers at once |

| Cleanroom Use | Suitable with proper finish | Suitable with proper finish |

Technical Specifications of Sanipure Powder Samplers

- Material: SS316L (standard), mirror-polished internal surfaces

- Lengths: 300 mm to 1000 mm

- Diameter Options: 20 mm, 25 mm, 32 mm, or custom

- Sampler Types:

- Single-cavity point sampler

- Multi-cavity slot sampler (2, 3, or 4 cavities)

- Inner rod with adjustable depth control

- Sterilization Support:

- Autoclavable

- Gamma/radiation safe

- CIP-compatible

All units are supplied with MOC, TC, CoC, surface finish reports, and passivation certificates.

Use Cases by Department

| Area | Recommended Sampler Type |

|---|---|

| Quality Control Lab | Multi-cavity for stratified sampling |

| QA Validation | Multi-cavity for audit-backed batch profiling |

| Production Floor | Single-cavity for quick check/sample pull |

| R&D Formulation | Single-cavity for testing excipient blends |

Case Study: Sampler Upgrade at a Sterile Powder Manufacturing Plant

A WHO-GMP certified facility upgraded from plastic scoops to SS316L multi-cavity powder samplers for final API batch validation.

Sanipure Supplied:

- Mirror-polished 4-cavity samplers with adjustable depth rod

- Full batch traceability via laser marking

- Autoclavable designs with ergonomic handle

✅ Result:

- Reduced total sampling time by 40%

- Increased consistency in stratified sampling

- Passed EU-GMP audit without deviation comments on sampling protocol

Why Choose Sanipure for Powder Samplers?

- ✅ Cleanroom-ready designs in SS316L, burr-free and GMP validated

- ✅ Options for custom cavity depth, grip design, and sampling length

- ✅ Used by India’s leading formulation, biotech, and nutraceutical manufacturers

- ✅ Supplied with full technical documents and QA traceability

GMP-Compliant Sampling Tools for Every Powder Type

At Sanipure Systems, we manufacture pharma-grade SS powder samplers to suit every product type and sampling method.

We offer:

- 🔩 Single-cavity and multi-cavity options, customizable in length and diameter

- 🧪 SS316L construction with mirror polish and passivation

- 📄 Supplied with MOC, CoC, TC, passivation, and surface roughness reports

- 💡 Engineering support for custom applications or sampling SOP compatibility

- 🚚 Fast shipping for pan-India pharmaceutical zones and global cleanroom suppliers

From batch release QA to in-process stratified sampling, we help you stay GMP-audit ready.

Buyer Tips: When to Use Single vs Multi-Cavity Samplers

✔️ Use multi-cavity samplers for layered or stratified batch testing

✔️ Use single-cavity samplers for homogenous or surface-only samples

✔️ Always confirm handle design and insertion depth before ordering

✔️ Request autoclavability certificate for sterile zone usage

✔️ Ask for laser marking to trace tools during audits or validations

→ Request a Custom Quote or Validation Drawing

🔍 Voice Search Optimized FAQs

Q1. What’s the difference between single and multi-cavity powder samplers?

Single-cavity samplers collect one sample per depth; multi-cavity collect layered samples in one insertion.

Q2. When should I use a multi-cavity powder sampler?

Use it when sampling from deep containers or when validating powder uniformity across different depths.

Q3. Are your samplers cleanroom- and GMP-compliant?

Yes. Our SS316L samplers are GMP-compliant, burr-free, passivated, and autoclavable.

Q4. Can I customize the number of cavities in the sampler?

Yes. We offer 2, 3, or 4-cavity models and custom versions on request.

Q5. Do I need SS316L or is SS304 sufficient?

SS316L is recommended for sterile, corrosion-prone, or critical zones. SS304 may be used in non-sterile areas.

Q6. Are your samplers suitable for API or fine powder sampling?

Yes. Our samplers are precision-finished to handle even micron-sized API powders without sticking.

Q7. Can these samplers be sterilized?

Absolutely. All designs are compatible with autoclave, gamma, and CIP cleaning.

Q8. Where can I buy stainless steel powder samplers in India?

From Sanipure Systems — trusted by leading pharma and biotech cleanroom operators.

Call to Action – Sample Smart. Sample Clean.

Whether you need quick in-process pulls or deep batch validation, the right sampler matters.

Choose stainless steel samplers that meet every regulatory and quality benchmark.

🧾 Request a Sampler Technical Drawing or Validation SOP

📥 Get Audit-Ready Certificates and Spec Sheets

📞 Speak with Our Pharma Sampling Tool Expert

→ Contact Sanipure Systems Now