What Are Stainless Steel Floor Strainers?

Stainless steel floor strainers are drainage fixtures placed at floor level to filter out solid debris while allowing water and other fluids to pass into the underlying drainage system. Typically made from SS304 or SS316L, these strainers are widely used in industrial kitchens, cleanrooms, commercial wash areas, and high-traffic zones.

They are known for:

- 🛠️ High load-bearing capacity

- 🧼 Corrosion resistance in wet, chemical, or food-processing zones

- 🔧 Long service life with minimal maintenance

Why Compare with Traditional Drainage Strainers?

Traditional floor strainers—made from plastic, cast iron, or GI (galvanized iron)—are still used in many buildings, but they often fail to meet the durability, hygiene, and compliance demands of modern commercial and industrial infrastructure.

This blog compares stainless steel strainers vs traditional alternatives across multiple performance factors such as:

- Flow rate

- Hygiene

- Installation and maintenance

- Life cycle cost

- Safety and compliance

Trends, Challenges & Common Buyer Questions

🔼 Industry Trends:

- Transition from cast iron to SS in hospitals, pharma plants, and food zones

- Use of anti-vibration SS strainers in commercial kitchens and airports

- Smart buildings and sustainable projects favoring long-life materials

❓ Common Questions:

- What’s the benefit of using stainless steel over plastic strainers?

- Are SS floor strainers strong enough for heavy loads?

- How do they perform in highly corrosive or hot water conditions?

- What kind of maintenance do they need compared to cast iron or GI?

🔗 Explore Stainless Steel Floor Strainers

Stainless Steel vs Traditional Floor Strainers: A Performance Comparison

At Sanipure, we design precision-engineered stainless steel floor strainers for modern sanitary, commercial, and industrial spaces.

Let’s break down how they compare to conventional options:

Material-Based Comparison Table

| Feature | SS304/SS316L Floor Strainer | Plastic Strainer | Cast Iron / GI Strainer |

|---|---|---|---|

| Corrosion Resistance | Excellent (SS316L ideal) | Poor (brittle over time) | Moderate, prone to rust |

| Load Bearing Strength | Medium to High | Low | High |

| Hygiene & Cleanability | Excellent (non-porous, food-grade) | Poor (biofilm risk) | Moderate |

| Maintenance | Low (no rust, no repainting) | Frequent replacement | Requires descaling, repainting |

| Service Life | 15–25 years | 2–5 years | 5–10 years |

| Safety (Slip/Odor/Backflow) | High (optional features) | Low | Moderate |

| Compliance (FSSAI/GMP/USFDA) | Yes | No | Partial |

| Sustainability | 100% recyclable, low lifecycle cost | Non-recyclable | Recyclable but high maintenance |

Real-World Use Cases

| Sector / Application Area | Why SS Strainers Are Preferred |

|---|---|

| Commercial Kitchens | Anti-clog design, odor prevention, easy cleaning |

| Hospitals & Labs | No microbial buildup, conforms to hygiene regulations |

| Airports / Metro Stations | Load-resistant, tamper-proof options available |

| Pharmaceutical Plants | GMP/FDA-compliant materials, zero contamination risk |

| Smart Buildings & IT Parks | Long-term ROI, aesthetic integration, modern surface finishes |

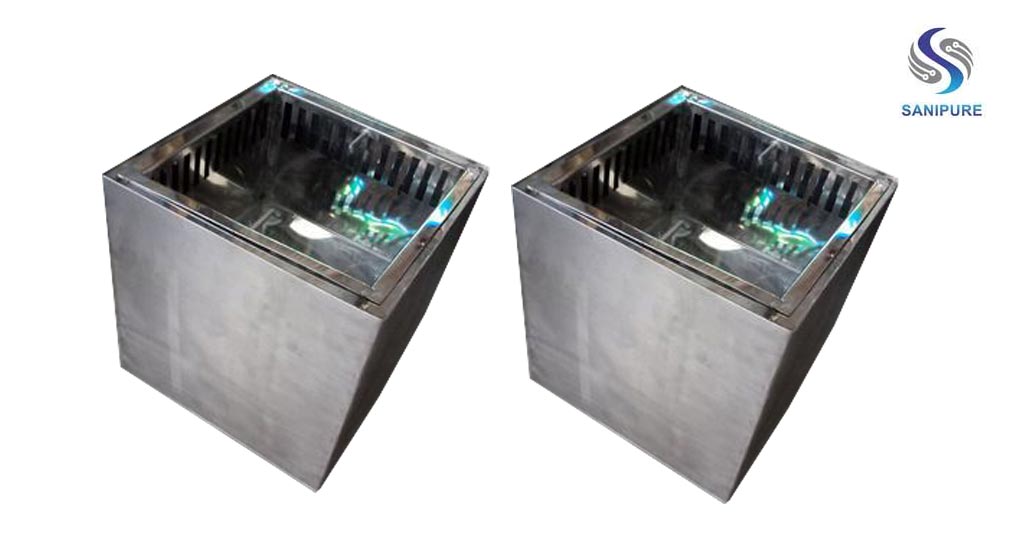

Key Features of Sanipure SS Floor Strainers

- ✅ Made from SS304 / SS316L, passivated for corrosion resistance

- ✅ Available in square, round, concealed, or anti-slip variants

- ✅ Optional features:

- Odor trap

- Removable basket strainer

- Anti-vandal grating

- Tamper-proof lock

- ✅ Compatible with modular SS drainage systems

- ✅ Load tested for heavy pedestrian and light vehicular traffic

Why Choose Sanipure SS Strainers Over Traditional Ones?

- ✅ Hygienic and safe for food, pharma, healthcare, and hospitality

- ✅ Lower life-cycle cost despite higher initial price

- ✅ Custom shapes, outlet sizes, and finishes available

- ✅ Trusted by hospitals, builders, EPCs, and facility managers across India

Bulk Supply, Customization & Institutional Approvals

At Sanipure Systems, we offer:

- 📦 Bulk-ready SS floor strainers for builders, EPCs, and maintenance teams

- 📐 Design flexibility: square, round, concealed, tamper-proof, or anti-slip

- 🛠️ Outlet and size customization based on project flow rate and tile finish

- 📄 Compliance documentation for FSSAI, USFDA, and cleanroom norms

- 🌍 Delivery across India with support for metro, airport, and hospital projects

We work with project managers, architects, and facility heads to help upgrade or replace traditional drainage systems with high-performance stainless solutions.

Buyer Tips: Upgrading from Traditional to SS Floor Strainers

✔️ Use SS316L for pharma, hospitals, and aggressive cleaning chemicals

✔️ Replace plastic strainers in high-traffic or kitchen areas immediately

✔️ For odor control, choose models with removable water seal traps

✔️ For long-term ROI, calculate life cycle cost—not just initial price

✔️ Match grating design with floor finish (anti-slip for wet zones, concealed for lobbies)

→ Talk to Our Drainage Specialist for Project Pricing

Voice Search Optimized FAQs

Q1. What is the advantage of using stainless steel floor strainers?

They offer better hygiene, corrosion resistance, and lifespan than plastic or iron options.

Q2. Can SS floor strainers handle high foot traffic or equipment load?

Yes. They’re available in load-bearing variants suitable for kitchens, malls, and airports.

Q3. Are SS strainers approved for food and pharma facilities?

Yes. Sanipure’s SS304/316L strainers comply with FSSAI, GMP, and USFDA standards.

Q4. Do SS strainers require frequent maintenance?

No. They resist scaling, rust, and odor—requiring only periodic cleaning.

Q5. Can SS strainers be retrofitted in older drainage systems?

Yes. We offer custom-fit options that match existing drain lines or grating covers.

Q6. How long does a stainless steel strainer last?

Typically 15–25 years with minimal upkeep, depending on usage conditions.

Q7. Do you offer custom shapes or outlet sizes?

Yes. Square, round, slot-drain, and concealed models are all available in custom sizes.

Q8. Where can I buy SS floor strainers in India or for export?

From Sanipure Systems — trusted by commercial and industrial clients across sectors.

Upgrade What’s Underfoot

Your drainage system is only as strong as your weakest link.

Switching to stainless steel floor strainers ensures safer, cleaner, and longer-lasting performance—no matter the application.

🧾 Download Product Brochure & Technical Specs

📥 Get Quote for Your Next Commercial or Industrial Project

📞 Schedule a Call with Our Drainage Expert

→ Contact Sanipure Today

Durable, Hygienic, Built to Last

Compared to plastic or cast iron, stainless steel floor strainers outperform in every area that matters—from cleanliness and strength to life span and regulatory compliance.

Drain smarter. Upgrade your infrastructure with Sanipure.