What Is a Stainless Steel Liquid Sampler in Pharma?

A stainless steel liquid sampler is a precision-engineered tool used to extract representative liquid samples from tanks, reactors, vessels, or process lines in pharmaceutical manufacturing. These samplers are typically made from SS316L to ensure chemical compatibility, non-reactivity, and cleanroom compliance, making them essential for quality testing, validation, and batch release.

Why Stainless Steel Samplers Are Essential in Pharma

Liquid samplers play a critical role in:

- 🧪 Ensuring batch integrity and uniformity

- 🔍 Conducting in-process and final QC tests

- 🔬 Supporting regulatory validation and documentation

- 🧼 Maintaining sterility and cross-contamination control

SS samplers are preferred over plastic or glass due to their durability, sterilization compatibility, and regulatory acceptance in clean environments.

Industry Trends & Buyer Challenges

🔼 Trends in Liquid Sampling:

- Demand for fully autoclavable, contamination-proof SS samplers

- Use of dedicated samplers per product line for GMP traceability

- Adoption of bottom-valve and inline sampling models in continuous processing

❓ Common Buyer Questions:

- Is SS316L required, or can I use SS304?

- Are samplers autoclavable and safe for cleanrooms?

- Which sampler design suits viscous or volatile liquids?

- How do I validate my sampling tools during audits?

🔗 Explore Stainless Steel Liquid Samplers

Where and How Stainless Steel Liquid Samplers Are Used

At Sanipure Systems, we design and supply GMP-compliant stainless steel liquid samplers tailored for:

- ✅ Batch sampling in sterile and non-sterile zones

- ✅ Process validation and in-process control

- ✅ Microbial and endotoxin-free sampling

- ✅ Regulatory compliance with FDA, WHO-GMP, and ISO norms

We offer a wide range of sampler designs for every application stage and fluid type.

Top Applications in Pharma and Biotech

| Department / Use Case | Role of SS Liquid Samplers |

|---|---|

| Quality Control (QC) | Uniform liquid batch sampling for assay and analysis |

| Production / In-Process Checks | Sampling from reactors, vessels, or WFI lines |

| Microbiology / Sterility Testing | Non-contaminating liquid collection from critical zones |

| R&D / Formulation Labs | Sample withdrawal during scale-up and trial batches |

| Packaging & Release | Sampling from bulk holding tanks before product filling |

These applications require accurate, contamination-free collection—a standard met reliably by SS316L liquid samplers.

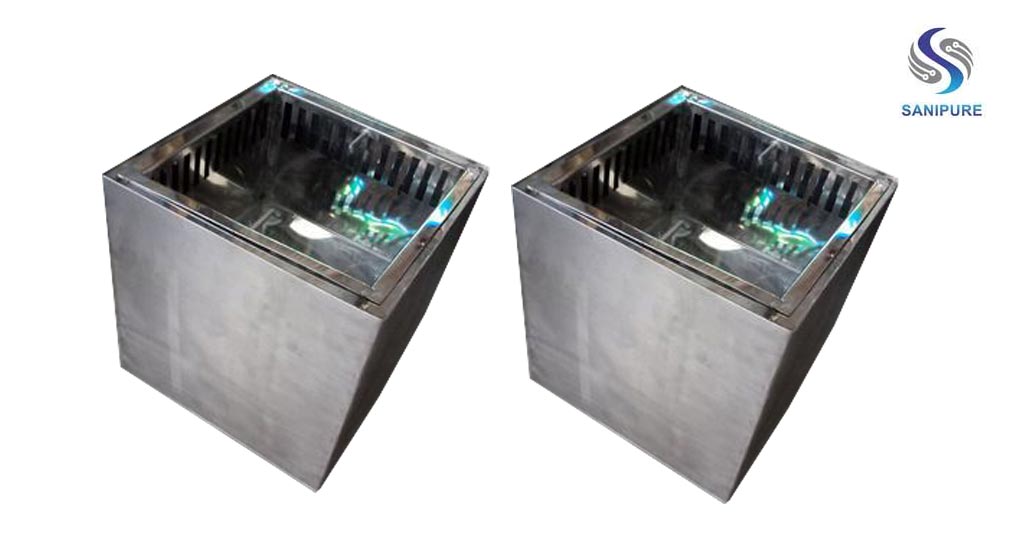

Technical Types of Liquid Samplers We Offer

- Closed-End Samplers – Simple dip sampling of liquids

- Open-End Samplers – Collects material when lowered into fluid

- Bottom Valve Samplers – Ideal for sampling from drums and vessels

- Inline Sterile Samplers – Installed directly in the fluid line

- Vacuum Sampling Bottles – For high-purity and cleanroom applications

All samplers are mirror-polished, burr-free, and fabricated to prevent microbial adhesion or residue retention.

Specifications & Features

- Material: SS316L (standard), electropolished interior/exterior

- Sizes: 25 ml to 1,000 ml or custom as per application

- Surface Finish: Mirror or 240-grit finish for hygienic handling

- Sterilization: Compatible with autoclave, CIP, SIP, gamma sterilization

- Documentation: MOC, TC, CoC, roughness report, passivation certificate

Case Study: Sampling in a Sterile Injectable Facility

A WHO-GMP-certified injectable manufacturer needed zero-contamination liquid sampling tools for WFI and buffer solutions in ISO Class 7 areas.

Sanipure supplied:

- SS316L bottom valve samplers with autoclavable storage cases

- Laser-marked traceable batch numbers

- Documentation kit: MOC, passivation, weld joint verification

✅ Outcome:

- Passed FDA and EU-GMP audits

- Reduced sampling errors by 65%

- Standardized samplers across three manufacturing blocks

Why Choose Sanipure for Liquid Samplers?

- ✅ Pharma-built for WFI, API, sterile, non-sterile, and high-purity fluids

- ✅ Supplied with complete GMP validation and material traceability

- ✅ Designed for cleanability, accuracy, and long-term sterility compliance

- ✅ Trusted by India’s top injectable, OSD, and biotech companies

Validation-Ready Liquid Samplers with Full Compliance Support

At Sanipure Systems, we offer:

- 🧪 Stainless steel liquid samplers in multiple designs for cleanroom and production use

- 🧼 Sterilization-ready options: autoclavable, CIP/SIP-compatible

- 📄 Complete documentation support: MOC, CoC, passivation, surface finish reports

- ⚙️ Support for custom capacities, handle lengths, valves, and sampling ports

- 🚛 Prompt delivery for pharma hubs and export shipment compliance

Whether you need WFI samplers, reactor samplers, or R&D scale sampling tools, we tailor every product to your audit and operational needs.

Buyer Tips: Selecting the Right Liquid Sampler for Your Pharma Facility

✔️ Use SS316L for sterile zones, solvents, or pH-sensitive fluids

✔️ Choose bottom valve or inline samplers for reactor or pipeline extraction

✔️ Request laser-marked or batch-traceable tools for regulatory SOPs

✔️ Ensure mirror finish with burr-free interiors to prevent microbial retention

✔️ Keep dedicated samplers per product or area to avoid cross-contamination

→ Request a Sample or Drawing of Our Liquid Samplers

Voice Search Optimized FAQs

Q1. What is a stainless steel liquid sampler used for in pharma?

It is used for collecting contamination-free samples of liquids like APIs, WFI, solvents, or buffers for QC or batch validation.

Q2. Which grade of stainless steel is used for pharma liquid samplers?

SS316L is preferred for its superior corrosion resistance and cleanroom compatibility.

Q3. Are your samplers autoclavable and sterile-zone compliant?

Yes. All our liquid samplers are autoclavable and suitable for ISO 5–8 zones.

Q4. What types of liquid samplers are available?

We offer open-end, bottom valve, closed-end, inline sterile, and vacuum samplers.

Q5. Do you provide documentation for GMP audits?

Yes. We provide MOC, CoC, passivation, finish, and batch traceability reports.

Q6. Can I get a customized sampler for a specific tank or pipe?

Yes. We offer custom lengths, capacities, valve types, and mounting options.

Q7. What capacity range is available in your liquid samplers?

Standard range is 25 ml to 1000 ml, with custom builds available on request.

Q8. Where can I buy pharma-grade stainless steel liquid samplers?

From Sanipure Systems — trusted by cleanroom and sterile pharma manufacturers across India.

Sample with Precision. Comply with Confidence.

Sanipure liquid samplers ensure that every drop you test reflects your batch quality.

Built to meet the strictest pharma and biotech standards, they keep your QA teams confident and your audits clean.

🧾 Request Technical Spec Sheet or Sterility Documentation

📥 Order a Sample or Cleanroom-Ready Unit

📞 Talk to Our Product Specialist Now

→ Contact Sanipure Systems

Every Test Starts with a Trusted Tool

In pharmaceutical manufacturing, one bad sample can lead to an entire batch recall.

Sanipure stainless steel samplers help you capture accurate, sterile, and compliant liquid samples—every single time.