In large-scale facilities, where durability, hygiene, and efficiency are crucial, stainless steel main drains are the ultimate solution. Whether it’s an industrial plant, a food processing unit, or a pharmaceutical cleanroom, the choice of drainage systems can make or break the operational effectiveness of your facility. In this article, we’ll explore why stainless steel main drains are the preferred choice for large-scale applications, delving into their unmatched durability, hygiene standards, versatility, and cost-effectiveness.

The Importance of High-Quality Drainage Systems

A drainage system in a large facility plays a critical role in maintaining hygiene, managing wastewater, and ensuring operational efficiency. Poorly designed or substandard drainage can lead to clogging, contamination, and increased maintenance costs. Stainless steel drains, with their robust construction and superior resistance to environmental stressors, solve these challenges effectively, offering long-term reliability and performance.

For facilities in Mumbai and across India, sourcing high-quality stainless steel drainage systems from reliable manufacturers and suppliers, such as Sanipure Systems, ensures adherence to industry standards and optimal functionality.

Key Features of Stainless Steel Main Drains

1. Unmatched Durability

Stainless steel, particularly grades like 304 and 316, is renowned for its strength and corrosion resistance. In high-traffic areas or facilities exposed to harsh chemicals, stainless steel can withstand wear and tear, making it a reliable choice for decades. For instance:

- Grade 316 Stainless Steel contains molybdenum, which enhances its resistance to chlorides and saline environments, ideal for facilities with extreme conditions.

- Resistance to Temperature Extremes ensures that the drains can handle both hot and cold wastewater without compromising structural integrity.

2. Hygiene and Cleanliness

Industries like food processing, pharmaceuticals, and healthcare require stringent hygiene standards. Stainless steel drains offer a smooth, non-porous surface that prevents the buildup of bacteria, mold, and other harmful microorganisms. Additionally:

- Easy-to-Clean Design: Stainless steel drains are compatible with Clean-in-Place (CIP) systems, allowing for automated cleaning with minimal labor.

- NSF/ANSI Standards Compliance: These drains meet hygiene certifications, ensuring safety in food and pharmaceutical environments.

3. Corrosion Resistance

Unlike cast iron or plastic, stainless steel resists rusting and chemical corrosion, even when exposed to cleaning agents, acids, and alkalis. This makes it ideal for:

- Chemical plants where corrosive substances are common.

- Food and beverage facilities that use acidic or alkaline cleaning solutions.

4. Eco-Friendly and Sustainable

Stainless steel is a recyclable material, making it an environmentally friendly choice. Its long lifespan also reduces the need for frequent replacements, minimizing waste and lifecycle costs.

Applications of Stainless Steel Main Drains

1. Food Processing Facilities

According to USDA data, floor drains are hotspots for bacteria like Listeria in food plants. Stainless steel drains eliminate this risk by providing a hygienic, easy-to-clean solution. They’re also resistant to high-pressure cleaning and extreme temperatures, making them perfect for:

- Dairy processing plants.

- Meat and poultry facilities.

- Bakeries and beverage production units.

2. Pharmaceutical Cleanrooms

Cleanrooms demand an aseptic environment. Stainless steel drains with O-ring gaskets and blind covers effectively seal off areas, preventing bacteria and debris from contaminating the workspace. ISO 14644-compliant systems ensure optimal air purity and cleanliness.

3. Industrial and Commercial Facilities

In manufacturing units, heavy traffic from forklifts and machinery necessitates robust drainage systems. Stainless steel drains are load-rated to withstand extreme weights and are designed for safety and durability.

Advantages Over Alternative Materials

| Feature | Stainless Steel | Cast Iron | Plastic |

| Durability | High | Medium | Low |

| Corrosion Resistance | Excellent | Poor | Moderate |

| Hygiene | Non-porous, easy to clean | Porous, bacteria buildup | Difficult to sanitize |

| Temperature Tolerance | Excellent | Low | Low |

| Longevity | 50+ years | 20-30 years | 10-15 years |

| Recyclability | 100% | Limited | Minimal |

Stainless steel outperforms other materials in almost every category, making it the top choice for large-scale facilities.

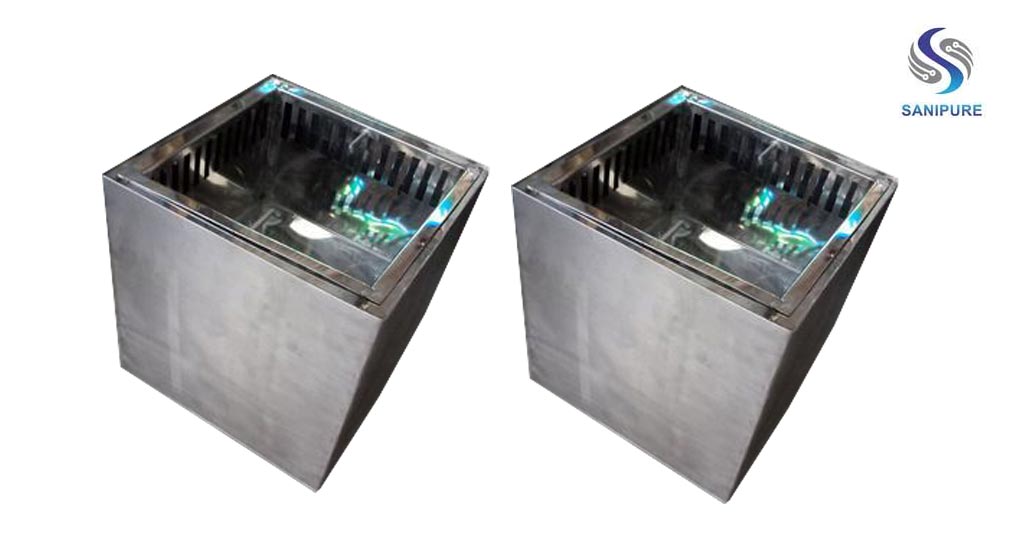

Why Choose Sanipure Systems for Stainless Steel Drains?

Sanipure Systems, based in Mumbai, India, is a trusted manufacturer and supplier of high-quality stainless steel drainage systems. Their products are designed to meet Indian and international standards, ensuring durability, hygiene, and efficiency. Key benefits of choosing Sanipure include:

- Customizable Solutions: Tailored drainage systems for unique facility needs.

- Superior Quality: Use of premium-grade stainless steel.

- Industry Expertise: Extensive experience serving food processing, pharmaceutical, and industrial clients.

- Comprehensive Product Range: From main drains to drain traps and complete systems.

Visit their stainless steel drainage system page to explore more.

FAQs About Stainless Steel Drains

- Why is stainless steel preferred for main drains in large facilities?

Stainless steel offers unmatched durability, corrosion resistance, and hygiene. Its eco-friendly nature and long lifespan make it a cost-effective choice for large-scale applications.

- What grade of stainless steel is best for drainage systems?

Grade 316 stainless steel is ideal due to its superior resistance to corrosion, especially in facilities exposed to chemicals or saline environments.

- How do stainless steel drains meet hygiene standards?

Their non-porous surface prevents bacterial growth, and their compatibility with CIP systems ensures thorough cleaning.

- Are stainless steel drains suitable for chemical plants?

Yes, they resist corrosive chemicals and withstand extreme temperatures, making them perfect for such environments.

- Where can I purchase high-quality stainless steel drains?

You can explore premium options from Sanipure Systems for reliable, high-performance drainage solutions.

Conclusion: Invest in Stainless Steel for Long-Term Efficiency

When it comes to large-scale facilities, stainless steel main drains are a clear winner. Their unparalleled durability, hygiene, and sustainability make them an essential component for any industrial or commercial setup. Choosing a trusted manufacturer like Sanipure Systems ensures you get products that meet stringent industry standards and deliver long-term value.

Ready to upgrade your facility’s drainage system? Contact Sanipure Systems today to discuss your requirements and find the perfect solution for your needs.